Gudai-Darri

Access

Rio Tinto

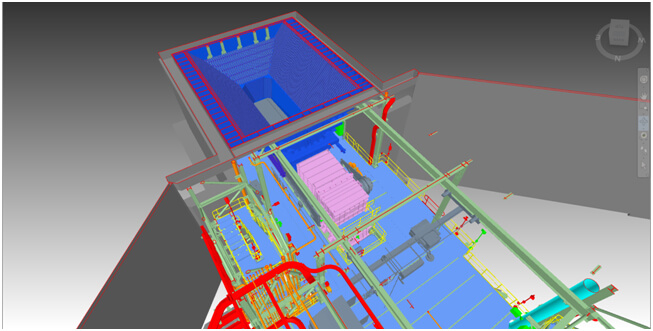

Replace 622 DEX Hopper

Maintenance Scope BN0102

- Replace damaged rail sections as necessary.

- Install new ceramic liners on the back wall.

- Perform parent metal repair.

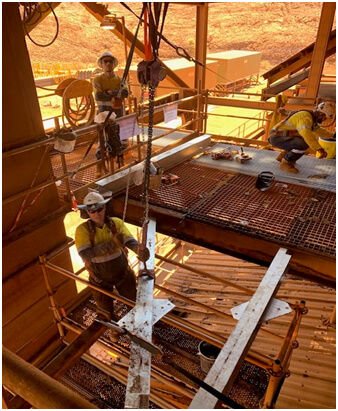

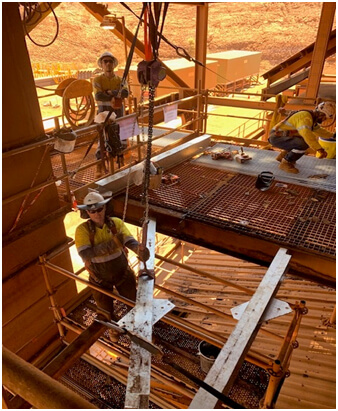

During the shutdown period, there will be ongoing crusher work above the team working in BN0102. To ensure safety, we will utilize the platform that rolls into the bin. This measure will help prevent any risk of falling objects from above, reducing the usability of the crane going in and out of the bin. However, Breight group will still be able to use the Overhead Crane (OHC) inside the bin to remove rails. If required, they may also use chain blocks to facilitate their work.

Replace Worn Rail Sections:

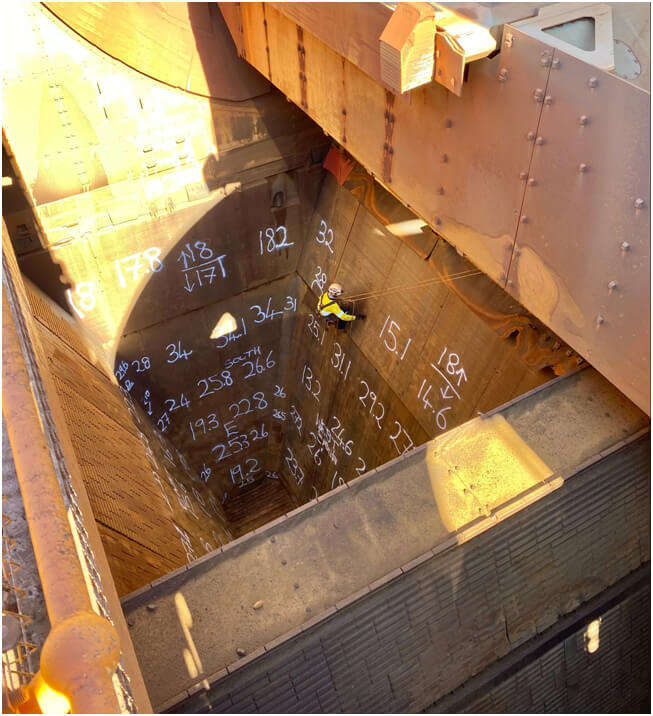

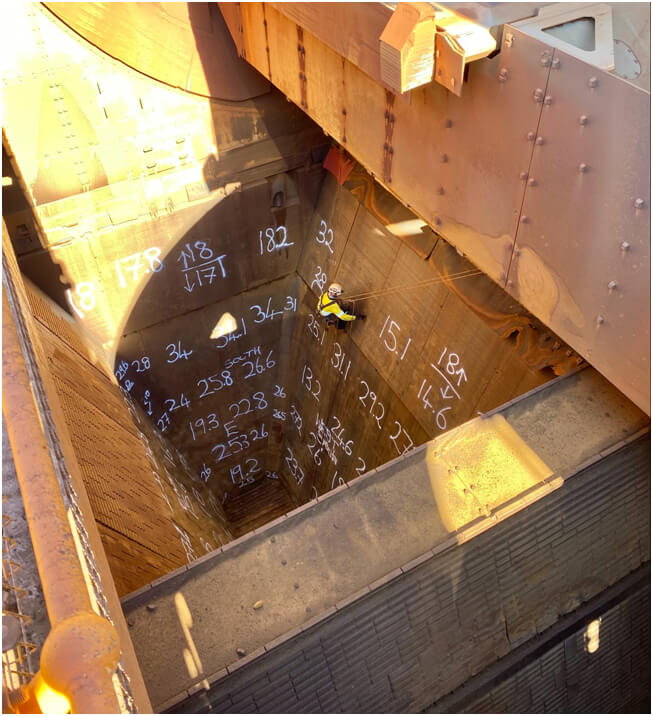

The worn rails are divided into two sections: upper and lower. The lower sections require replacement due to wear. Based on available images, it appears that there are approximately 6 or 7 lengths of rail on both the left and right-hand walls (direction of flow with apron feeder), and 10 to 11 lengths of rail on the back wall. The rails on the left and right-hand walls will need to be drilled offsite when ordered, ensuring the keeper plate matches the bin’s design.

Details of Replacement Sections:

- Right Wall: 7 x Lengths – Part number: BN102-01R100

- Left Wall: 7 x Lengths – Part number: BN102-01R100

- Back Wall: 11 x Lengths – Part number: BN102-01R104

Note: Consider flipping the back wall rails to extend their lifespan, as the top section may experience less wear.

To access the rail replacement, ropes will be set up from the level above using prebuilt anchor points and dropped through the concrete flo\oring into the bin. Rigging will require 3.5T Pinkies with a 16mm thread. Additionally, a scaffold will be erected outside before the shutdown to provide easy access to the bolts for the rails.

Breight will remove the bottom sections of the rail and lower them onto the apron feeder using the OHC (Overhead Crane) inside the bin. After removing all worn sections, the primary crusher maintenance platform will be taken out, allowing the old sections to be rigged and removed from the bin. The new rail sections will then be brought in and placed on the apron feeder, followed by replacing the rails in reverse order.

Rails, bolts, nuts, and keeper plates will be ordered based on shop drawings to minimize onsite cutting and drilling requirements for a smoother execution of the work.

Ceramic Liner Replacement with Parent Metal Repair:

The removal of ceramic wear liners will be carried out using Suitable Davies tooling and equipment or rattle guns to carefully detach and extract the ceramic wear liners from the bin wall.

Once the ceramic wear liners have been removed, a thorough inspection of the parent metal behind the liners will be conducted. Based on the condition and repair requirements, Breight will cut out the parent metal back to the gussets and replace it with new mild steel sections. the holes will need to be drilled and or slotted depending on the type of fastener.

Interactions with the rail replacement work will require agreeing on priorities at the beginning of the shutdown once a full visual inspection can be carried out.

Other Projects

VIEW ALL PROJECTS

Learn from

the best

Our range of nationally recognised training ensures workforces are meeting mandated licencing and legislative requirements. We help individuals to gain skills that enable them to confidently step into project teams.

VIEW TRAINING COURSES

Have a project in mind?

Our dedicated team is committed to achieving high-quality, efficient and safe project outcomes.